High-accuracy and long-life eRC Series has evolved and arrived in SC Series paper cutting machines. New functions are added in pursuit of helpfulness and safety. The ease of maintenance and efficiency are also enhanced. These paper cutting machines assure future use with full network connectivity. The technology and ideas of ITOTEC mastering every detail in the paper cutting job field are fully installed in this new model.

Line-up

Max. cutting width : 1030mm

Max. cutting width : 1168mm Max. cutting width : 1370mm Major new functions

A safety beam guard is installed outside at both ends.

Connect a USB memory or

the like to input or output

data. The knife speed and maximum backgauge advance speed are

improved.

Standard features

The touch panel is easy to observe and large. The maximum clamp pressure

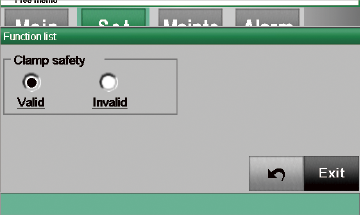

is increased. The phototube-assisted clamp ascent safety function is

activated during pedal operation. The cover of the internal access window is

changed to the gate type. The pedal high-pressure function is installed as a

standard feature. Soft Clamp. A waste removal window is installed. The

operation button is provided with a key top, improving the durability. The dent

at the bottom of the main body is eliminated, increasing stability.

The touch panel is easy to

The maximum clamp pressure is

increased.

The phototube-assisted clamp

ascent safety function is activated

during pedal operation.

The cover of the internal access

window is changed to the gate

type.

The pedal high-pressure function

is installed as a standard feature.

Soft Clamp.

A waste removal window is

installed.

The operation button is provided

with a key top, improving the

durability.

The dent at the bottom of the main body is eliminated, increasing stability. Optional features

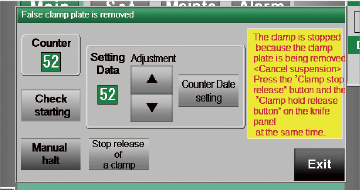

Front removal/installation of the false clamp has become possible.

A manual knife lifter is prepared. Resin at the backgauge comb teeth. LED cut line.

Front removal/installation of the

false clamp has become possible

(Option).

A manual knife lifter is prepared

(Option).

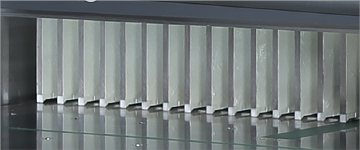

Resin at the backgauge comb

teeth (Option).

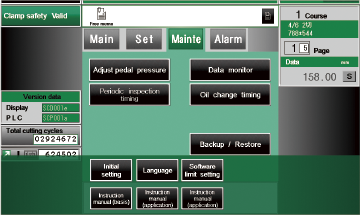

LED cut line (Option). High-efficiency work is aimed at. Large screen with substantial helpful functions.

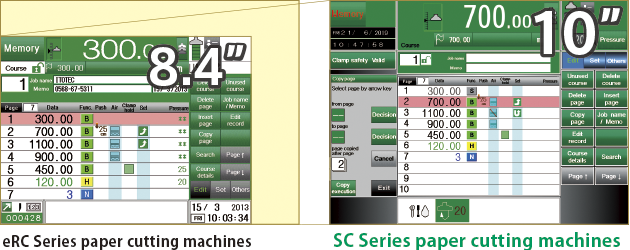

Bright and visible TFT 10” color LCD touch panel. Because 10 pages are

displayed at a time (center hold type scroll), course contents can be checked

easily, contributing to reduction of entry errors. The language selection

function changes the language among Japanese, English, Chinese (simplified

or traditional), Thai, Dutch, Spanish and German. Operation can be conducted

in your familiar language. The screen size is increased.

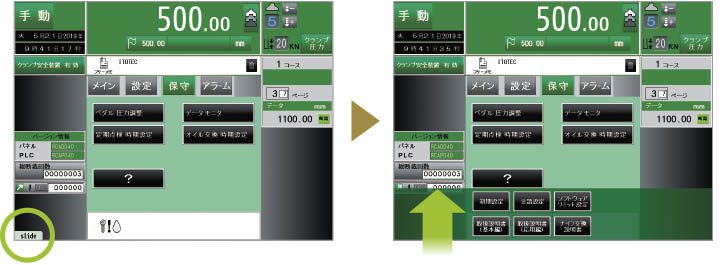

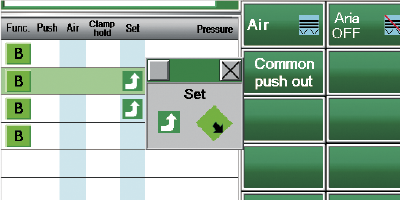

Popup window function

An auxiliary window is stored outside the screen.  Size agreement detection function. Course list view and detail settings. Setting direction window. Print deviation correction function. Automatic knife timing variation function. Clamp pressure setting. Alarm record function. Message window/alarm function. Size agreement detection function

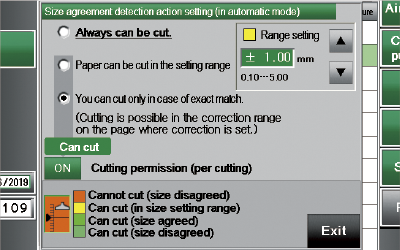

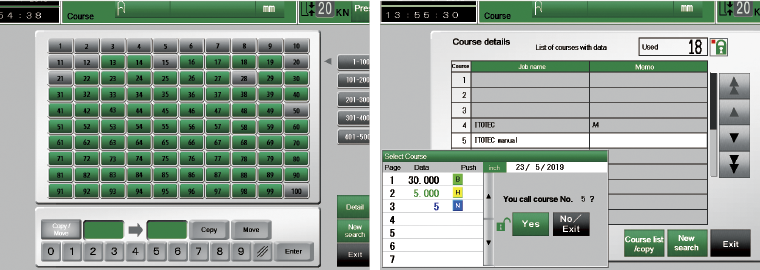

With this function, paper cutting is disabled if the stored data does not agree Course list view and detail settings

Information about the vacant or occupied course is displayed on the number panel with 100 courses at a time. The course can be moved or copied on the number panel. Write down the job name or memo of each course to perform an AND search and look at the details of the job on course details view. Setting direction window

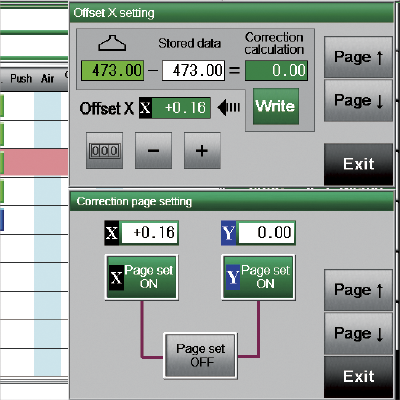

The work setting procedure and direction of paper rotation are displayed clearly in animation. Print deviation correction function

With this function, deviation of the press sheet from the stored cutting data is corrected. Even if the actual press sheet is dislocated, cut according to register marks. Deviation from the stored data is automatically calculated and the offset is stored. There is no need to enter the offset again. Automatic knife timing variation function

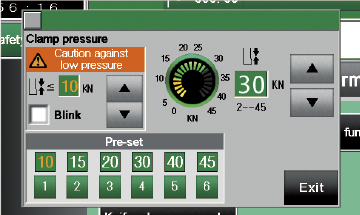

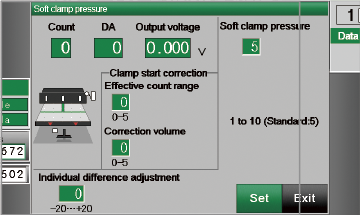

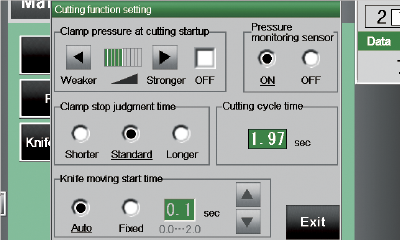

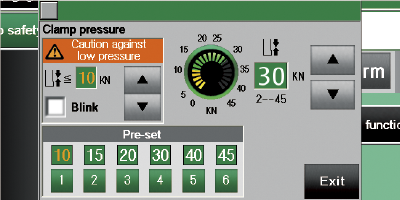

The paper pressed under the clamp is automatically judged. Even if the stacked paper is high or if paper is pressed with pedal operation, the knife is driven immediately. The time needed for a cutting cycle can be reduced. Clamp pressure setting

The clamp pressure setting can be entered on the display. The pressure is entered numerically in the range from 2KN to 45KN in 1KN increments, so that variation in the pressure setting is eliminated. The pressure can be preset in each course or each page in addition to presetting in 5KN increments. The pressure can be defined optimally according to the characteristic of the cut item or cutting position, eliminating waste paper caused by the pressure error. Complete cutting operation is supported. Alarm record function

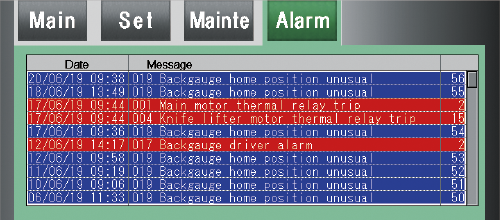

Description of the failure in the alarm view is stored with the date, time and message. This memory is helpful during maintenance work. Message window/alarm function The replacement timing of the knife or oil is indicated with an icon. The current state of the paper cutting machine is visible. Reliable mechanism In pursuit of high accuracy, productivity and safety Lasting accuracy! Powerful

The double sliding swing drive, a tradition of Itotec, which moves the left and right worm gears independent of each other to move the knife, and our original swing angle, which is produced by pulling while pushing, together contribute to an excellent accuracy. Their reliability is recognized at job fields all over the world, and our cutting machine operates for “cutting” jobs in various fields. (eRC82 adopts single sliding drive.) Safety units having passed

The two-hand operation type safety unit of the cutting switch and the safety beam guard are installed in all models as standard features. These units have passed model tests based on the Industrial Safety and Health Law enforced by the Ministry of Health, Labour and Welfare. Relevant items

Law in cutting machine? Labour and Welfare. Assured with compatibility with The cloud server of “Scissor HANDS AI” can be accessed as a supporting paper cutting machine where the best cutting procedure is instantly prepared according to JDF data. (SCISSOR HANDS is optional.) Relevant items

Scissor HANDS Total support for paper Accurate gear

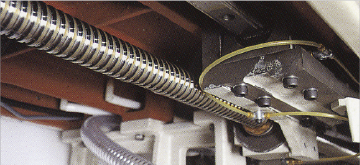

Hard balls are arranged at more than 100 points inside the mechanism for moving the backgauge. Smooth rotation generated with rolling friction realizes accurate positioning. The L.M. guide is also equipped with small hard balls to avoid deviation. Safety bolt

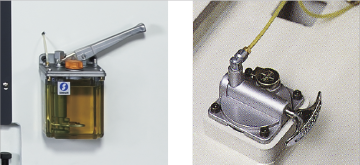

If cutting is made forcefully with a dull knife or if hard matters such as a metal are erroneously cut, shear bolts built in the left and right rods are broken to protect the machine against damage. If the shear bolt is broken, a limit switch is activated to stop the knife immediately. Soft Clamp The soft clamp method, with which the clamp pressure applied upon the press of the clamp pedal is suppressed to a low pressure, is adopted as a standard feature. Installation/Removal of knife An optional manual knife lifter is prepared. (Knife change fixture with a cover is also attached.) The knife can be installed or removed smoothly. Oil maintenance

A central lubrication pump is installed at each of the main body of the machine and the backgauge. The operator needs to merely activate the pump in addition to oil and grease supplied at several points. Chrome plated air table

Air blower valves are installed in the main table and side table. Even large paper can be handled without difficulty. The table top is chrome-plated to suppress rust generation and protect paper from foulness. Cutting line view The cutting line is projected on paper before the clamp is lowered. The fit-to-actual-size memory can be easily stored. Specifications of SC Series paper cutting machine

Additional function and optional equipment

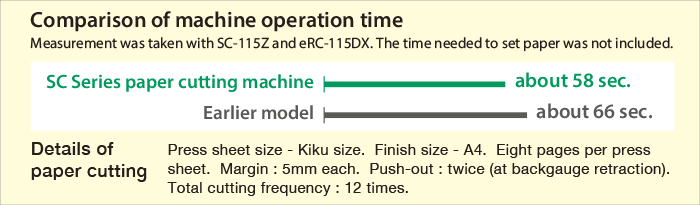

In a comparison experiment, the cutting speed was better than that of an earlier model, indicating a time reduction effect.

Comparison of machine operation time

The sensor reaction area has been widened for safer maintenance services, knife replacement and so on. The location of the device can be changed to inside, similarly to the earlier model.

Details of paper cutting Press sheet size - Kiku size. Finish size - A4. Eight pages per press sheet. Margin : 5mm each. Push-out : twice (at backgauge retraction). Total cutting frequency : 12 times. For opinions requests to the products of ITOTEC contact.

Tel 81-568-67-5311 Fax 81-568-68-0495 Email export@itotec.co.jp Site MapSC series paper cutting macine

eRC series paper cutting machinePaper feeding / discharging equipment、 Labor saving unitSCISSOR HANDSOverhauled paper cutting machinesUseful informationLibrary / Manual, Guidebook© ITOTEC CO.,LTD. ALL RIGHTS RESERVED | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||