|

Evolving paper cutting machine

Support for small size up to wide size

|

|

|

|

|

|

|

eRC Series paper cutting machine

Model lineup

Compact machine with full functions. A multi-function touch panel contributes to high quality and speedy cutting operation.

Cutting operation with double sliding drive, a tradition of Itotec,

boasts preeminent accuracy.

Large widths and wide sizes are powerfully cut.

Various non-paper materials are supported.

Ready-to-use cutting-edge functions are installed in all models.

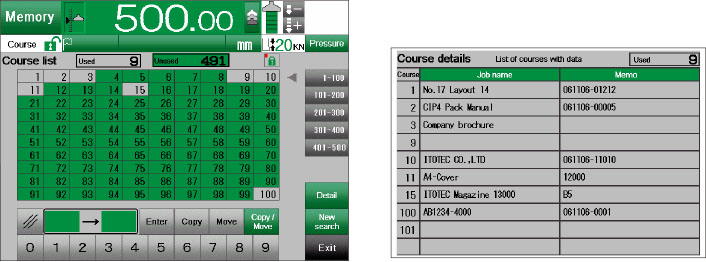

Course list and detail settings

The used/unused course data is displayed on the number panel for every 100 courses.

Each course can be easily moved or copied. Job names and memo written in the course can be searched for from the detail course view through AND search.

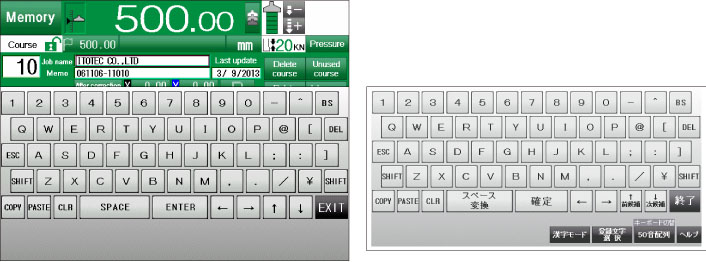

Clamp pressure setting

The clamp pressure setting affecting the cutting quality can be entered at the display. Enter a value between 2KN and 40KN in 1KN increments. Variation in the pressure setting can be suppressed. The value can be preset in 5KN increments and the pressure setting can be varied among courses and pages. The pressure setting adjusted for each item and each cutting position can avoid cutting errors caused by pressure errors.

Keyboard for Japanese and English languages

A keyboard is displayed on the touch panel. Use it to enter the job name and memo. The keyboard can be selected between JIS and Japanese kana syllabary layouts so that the operator can choose the desired one.

Backgauge acceleration control

A series of backgauge motions are controlled. Best for prevention of workpiece collapse. The general speed, start-up, deceleration and stop can be minutely adjusted.

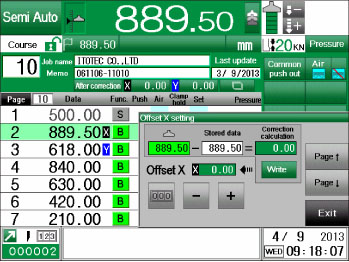

Print shift compensation function

With this new function, the position shift between the cutting data and the print can be compensated for. When the item is cut at the register mark, the shift from the stored data is automatically compensated for and stored in memory. Even though there is a shift in the print position, there is no need to enter the offset again.

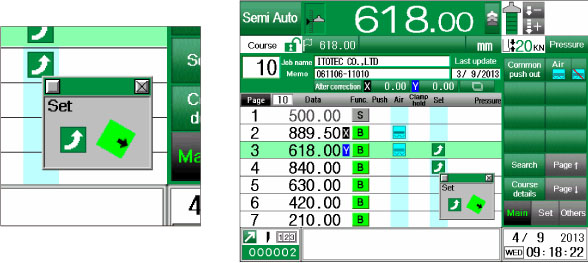

Setting direction window

The workpiece setting and paper rotation direction are displayed in a graphic animation.

You can work assuredly while looking at instructions on the display.

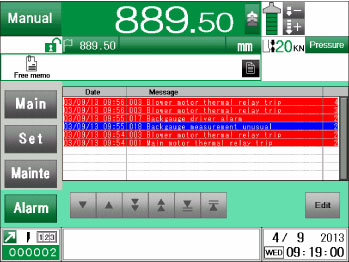

Alarm history function

The alarm failure history function keeps memory of the date, time and details of the failure accurately. The service personnel refer to this data to comprehend the machine state quickly, so that the maintenance work is speedy.

Message window and alarm function

Knife change and oil change notices are displayed with corresponding icons. The current state of the cutting machine is at a glance.Knife change and oil change notices are displayed with corresponding icons. The current state of the cutting machine is at a glance.

Quick start, no delay in work

The control panel serving as a core of the eRC Series cutting machine contains the program of functions necessary for the operation of the cutting machine only. It starts immediately when the power is turned on, so that you can start to work immediately.

Accuracy, productivity and safety are securely pursued.

Lasting accuracy! Powerful double sliding drive

The double sliding swing drive, a tradition of Itotec, which moves the left and right worm gears independent of each other to move the knife, and our original swing angle, which is produced by pulling while pushing, together contribute to an excellent accuracy. Their reliability is recognized at job fields all over the world, and our cutting machine operates for “cutting” jobs in various fields. (eRC82 adopts single sliding drive.) |

Safety units having passed model tests

The two-hand operation type safety unit of the cutting switch and the safety beam guard are installed in all models as standard features. These units have passed model tests based on the Industrial Safety and Health Law enforced by the Ministry of Health, Labour and Welfare.

|

Assuredness backed by support of CIP4/JDF data(Option)

You can simply add Itotec’s genuine “CIP4 Pack” (option) to the eRC cutting machine to realize the function. |

Total support for paper feeding up to paper discharge

|

Chrome plated air table |

Safety bolt |

|

Air blower valves are installed in the main table and side table. Even large paper can be handled without difficulty. The table top is chrome-plated to suppress rust generation and protect paper from foulness. |

If cutting is made forcefully with a dull knife or if hard matters such as a metal are erroneously cut, shear bolts built in the left and right rods are broken to protect the machine against damage. If the shear bolt is broken, a limit switch is activated to stop the knife immediately.

|

Cut line view

The cutting line is displayed on paper before the clamp is lowered. The function is helpful when the real-item cutting position is stored. |

Installation/Removal of knife

Ascent and descent of the clamp are used to remove the knife of even the large machine easily. |

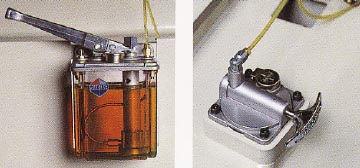

Oil maintenance

A central lubrication pump is installed at each of the main body of the machine and the backgauge. The operator needs to merely activate the pump in addition to oil and grease supplied at several points. |

Accurate gear

Hard balls are arranged at more than 100 points inside the mechanism for moving the backgauge. Smooth rotation generated with rolling friction realizes accurate positioning. The L.M. guide is also equipped with small hard balls to avoid deviation. |

Soft Clamp

The soft clamp method, with which the clamp pressure applied upon the press of the clamp pedal is suppressed to a low pressure, is adopted as a standard feature. |

|

| Model |

eRC-82 |

eRC-100DX |

eRC-115DX |

eRC-137DX |

| Knife driving method |

Single sliding drive |

Double sliding drive |

Double sliding drive |

Double sliding drive |

| Cutting width |

32 1/3" 820mm |

40 1/2" 1030mm |

46" 1168mm |

54" 1370mm |

| Cutting depth |

32 1/3" 820mm |

39" 1000mm |

45 5/8" 1160mm |

52" 1320mm |

| Clamp opening |

5 1/8" 130mm |

6 1/2" 165mm |

6 1/2" 165mm |

6 1/2" 165mm |

| Min. cutting size |

With false clamp |

70mm |

85mm |

85mm |

105mm |

| Without false clamp |

27mm |

27mm |

27mm |

27mm |

| Front table length |

25 1/2" 650mm |

27 1/2" 700mm |

27 1/2" 700mm |

27 1/2" 700mm |

| Table height |

33 1/2" 850mm |

34 1/2" 875mm |

34 1/2" 875mm |

34 1/2" 875mm |

| Machine size |

width |

78 1/2" 1995mm |

104 3/4" 2660mm |

109 3/8" 2790mm |

118 1/2" 3010mm |

| height |

59 4/5" 1520mm |

64 1/2" 1660mm |

65 1/3" 1660mm |

64 1/2" 1660mm |

| length |

82 1/3" 2090mm |

96" 2440mm |

102 3/4" 2610mm |

108 1/2" 2760mm |

| Knife stroke |

42times/min |

42times/min |

42times/min |

42times/min |

| Knife dimensions |

995×130×11.1mm |

1270×150×12.7mm |

1410×150×13.7mm |

1610×150×13.7mm |

| Max. backgauge advance speed |

150mm/min |

225mm/min |

225mm/min |

225mm/min |

| Min. clamp pressure |

4kN |

4kN |

4kN |

4kN |

| Max. clamp pressure |

30kN |

40kN |

40kN |

40kN |

| LCD monitor |

•Display type : TFT color LCD touch panel •Display size : 8.4" •Memory : 500 courses 25000 pages (50 pages per course) •Operation mode : Memory mode. Manual mode. Semi-automatic mode. Full automatic mode •Display language : Japanese. English. Chinese(simplifled/traditional). Thei. Dutch. Spanish.German •Keyboard : Japanese syllabary layout. JIS layout(QWERTY layout) selection Input increment : mm. cm. inch. Shaku •Input value : 0.01mm •Max. setting : 9999.99mm (However, within range limit) •Min. setting : 0.01mm (However, within range limit) •Setting time About 4 sec |

| Main motor |

2.2kw |

3.7kw |

3.7kw |

3.7kw |

| Backgauge motor |

0.4kw |

0.75kw |

0.75kw |

0.75kw |

| Blower motor |

0.4kw |

0.4kw |

0.4kw |

0.75kw |

| Total power required |

3kw |

4.85kw |

4.85kw |

5.2kw |

| Net weight |

2,500kg |

3,700kg |

4,100kg |

4,500kg |

| Model name |

eRC-160DX |

eRC-170DX |

eRC-200DX |

eRC-250DX |

| Knife driving method |

Double sliding drive |

Double sliding drive |

Double sliding drive |

Double sliding drive |

| Cutting width |

63" 1600mm |

67" 1700mm |

78 3/4" 2000mm |

98 1/2" 2500mm |

| Cutting depth |

63" 1600mm |

67" 1700mm |

78 3/4" 2000mm |

98 1/2" 2500mm |

| Clamp opening |

6 1/2" 165mm |

6 1/2" 165mm |

5 1/8" 130mm |

6 1/2" 165mm |

| Min. cutting size |

With false clamp |

105mm |

105mm |

105mm |

125mm |

| Without false clamp |

27mm |

27mm |

27mm |

35mm |

| Front table length |

27 1/2" 700mm |

29 1/2" 750mm |

29 1/2" 750mm |

29 1/2" 750mm |

| Table height |

35" 890mm |

35" 890mm |

34 1/2" 875mm |

35" 890mm |

| Machine size |

Width |

139 1/3" 3540mm |

143 1/3" 3640mm |

153 1/2" 3900mm |

177 1/2" 4515mm |

| Height |

68" 1730mm |

68" 1730mm |

66 1/2" 1690mm |

68" 1730mm |

| Length |

130 3/4" 3320mm |

133" 3380mm |

144" 3660mm |

164 1/2" 4180mm |

| Knife stroke |

42times/min |

42times/min |

42times/min |

42times/min |

| Knife dimensions |

1850×165×14.2mm |

1950×165×14.2mm |

2260×160×14.2mm |

2760×165×14.2mm |

| Max. backgauge advance speed |

225mm/min |

225mm/min |

225mm/min |

200mm/min |

| Min. clamp pressure |

4kN |

4kN |

4kN |

4kN |

| Max. clamp pressure |

40kN |

40kN |

40kN |

40kN |

| LCD monitor |

•Display type : TFT color LCD touch panel •Display size : 8.4" •Memory : 500 courses 25000 pages (50 pages per course) •Operation mode : Memory mode. Manual mode. Semi-automatic mode. Full automatic mode •Display language : Japanese. English. Chinese(simplifled/traditional). Thei. Dutch. Spanish.German •Keyboard : Japanese syllabary layout. JIS layout(QWERTY layout) selection Input increment : mm. cm. inch. Shaku •Input value : 0.01mm •Max. setting : 9999.99mm (However, within range limit) •Min. setting : 0.01mm (However, within range limit) •Setting time About 4 sec |

| Main motor |

5.5kw |

5.5kw |

7.5kw |

7.5kw+3.7kw

(Main+Pump motor) |

| Backgauge motor |

0.75kw |

0.75kw |

1kw |

1.5kw |

| Blower motor |

1.5kw |

1.5kw |

1.5kw |

1.5kw |

| Total power required |

7.75kw |

7.75kw |

10kw |

14.2kw |

| Net weight |

5,500kg |

5,800kg |

6,200kg |

8,000kg |

Designs and specifications are subject to change with/out notice.

|